If you work with single‑mode optical networks—FTTH, PON, CATV, 5G fronthaul—you will run into the SC/APC fiber optic adapter (sometimes called an SC/APC coupler) almost immediately. This small, inexpensive component is critical for aligning and mating two SC/APC connectors while preserving low insertion loss and ultra‑high return loss performance. In this beginner-friendly guide, we’ll explain what it is, why the “APC” matters, the different types you can buy, how to select the right model, and how to install and test it correctly.

What is an SC/APC Fiber Optic Adapter?

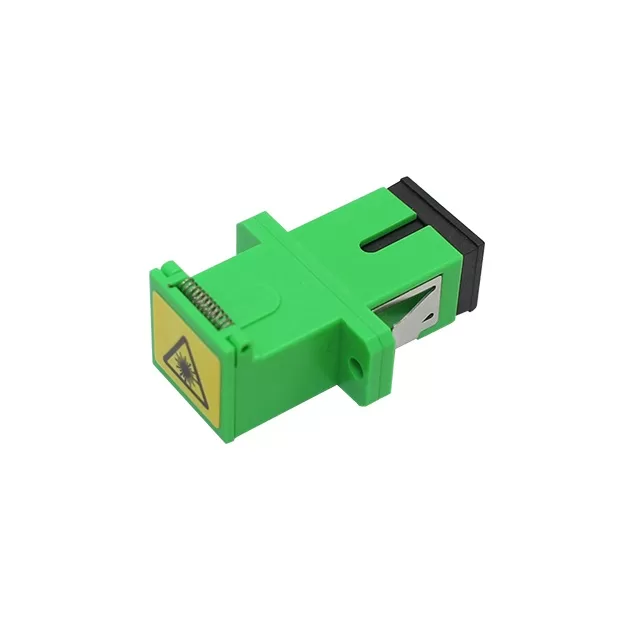

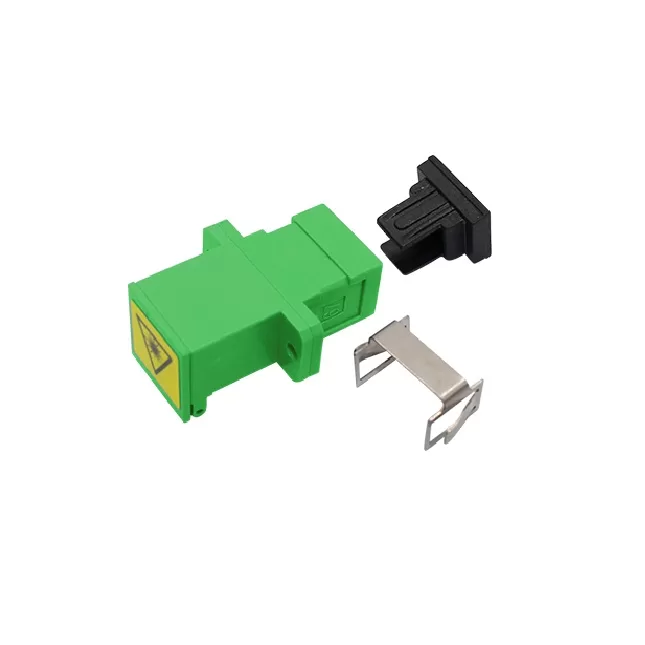

Un SC/APC fiber optic adapter is a passive mechanical interface used to join two SC connectors that have angled physical contact (APC) ferrules, typically polished at 8°. The adapter houses a precision alignment sleeve—most commonly zirconia ceramic—that keeps the two ferrules perfectly aligned to minimize optical loss. The body is usually green to visually indicate APC compatibility (as opposed to blue for UPC and beige/aqua for multimode PC/UPC).

Key quick facts:

- Connector style: SC (Subscriber Connector / Square Connector)

- Polish: APC (Angled Physical Contact, ~8°)

- Color code: Green housing for easy identification

- Typical performance: Insertion Loss (IL) ≤ 0.2 dB (typical), Return Loss (RL) ≥ 60 dB (typical) for APC

- Use case: Single-mode networks where reflections must be minimized (FTTH, CATV, PON, RF-over-fiber, high-power links)

SC vs. APC: Why the Angle Matters

You’ll often see SC connectors with two polish options: SC/UPC (Ultra Physical Contact) and Carolina del Sur/APC (Angled Physical Contact). The difference is in how reflections are handled:

- UPC (flat/ultra-polished): Lower insertion loss but higher back reflection (typical RL ≥ 50 dB). Better for digital systems less sensitive to reflections, like many data center links.

- APC (8° angle): Slightly higher insertion loss but much better return loss (typical RL ≥ 60 dB, often ≥ 65 dB). Ideal for systems where reflections can cause signal distortion, such as analog CATV and certain PON architectures.

Bottom line: Choose Carolina del Sur/APC when back reflection control is critical. You must also never mate APC to UPC—the angled and straight faces will not seat correctly, causing significant loss and damage risk.

How an SC/APC Adapter Works

Internally, the adapter is simple but precise:

- Alignment sleeve (usually zirconia ceramic) centers and aligns the 2.5 mm ferrules of the two SC/APC connectors.

- Housing (often high-strength polymer or metal) provides mechanical stability and panel-mount features (flanges).

- Retention clips and dust caps protect and secure the mated connectors.

Because SC/APC connectors have angled end-faces, the adapter must be designed specifically for APC to maintain the correct ferrule orientation and pressure.

Typical Specifications to Know

When you’re evaluating or comparing SC/APC fiber optic adapters, pay attention to:

- Pérdida de inserción (IL): Typically ≤ 0.2 dB (max 0.3–0.5 dB depending on grade).

- Pérdida de retorno (RL): ≥ 60 dB for APC (much higher than UPC).

- Mating Durability: 500–1,000 cycles typical without significant performance degradation.

- Operating Temperature: Commonly −40 °C to +75 °C (check datasheet for harsh environments).

- Sleeve Material: Zirconia ceramic offers the most stable alignment and durability; phosphor bronze sleeves are cheaper but less precise—fine for some secondary applications.

- Cumplimiento: Look for conformity to IEC, TIA/EIA (e.g., FOCIS-3 for SC), and RoHS standards.

Common Types of SC/APC Fiber Optic Adapters

1) By Channel Count

- Simplex: One fiber channel. Most typical for SC/APC.

- Duplex: Two channels side-by-side to support two SC/APC connectors (Tx/Rx or two wavelengths).

2) By Hybridization

- SC/APC to SC/APC: The standard.

- SC/APC to LC/APC (or other hybrid types): For cross-format connections.

3) By Housing & Features

- Flanged (with ears): Panel or bulkhead mount.

- Shuttered / Dust-proof: Includes an auto-shutter to protect the sleeve and avoid laser exposure.

- Metal vs. Plastic Housing: Metal offers better robustness and often better EMI shielding; plastic is lighter/cost-effective.

- Codificación de color: Green bodies to denote APC; sometimes with white or black dust caps.

4) By Application / Grade

- Standard Grade: For typical FTTH/PON deployments.

- Carrier/Telecom Grade: Tighter IL/RL specs, higher durability, wide temp ranges.

- Outdoor/Harsh-Environment Grade: UV-resistant, IP-rated variants for cabinets and outside plant (OSP) uses.

Where SC/APC Fiber Optic Adapters Are Used

- FTTH / FTTx (PON, GPON, XGS-PON, 10G-PON): Minimizes reflections that can affect splitters and ONTs.

- CATV / RF-over-Fiber: Analog signals are highly sensitive to reflections; APC is a must.

- 5G / Wireless Fronthaul & Backhaul: For low-reflection, high-stability single-mode runs.

- Passive Optical LANs (POL): Enterprise PON deployments.

- Test & Measurement: High-precision APC references in labs and field test sets.

While SC/APC can also appear in data center contexts (especially where PON meets enterprise networks), UPC is generally more common for digital, short-reach, multi-mode data center links.

How to Choose the Right SC/APC Fiber Optic Adapter

Use this selection checklist to make sure you buy the right part:

- Polish Type: Confirm APC (green) to match your SC/APC connectors.

- Form Factor: Simplex or duplex? Flanged for panel mounting?

- Actuación: Target IL ≤ 0.2 dB, RL ≥ 60 dB (or better for CATV).

- Sleeve Material: Prefer zirconia ceramic for critical links; bronze for lower-cost, less demanding use.

- Compliance & Quality: Meets TIA/EIA, IEC, Telcordia; check the vendor’s QC regime (100% IL/RL test reports are ideal).

- Ambiente: Temperature range, flame rating, UV resistance, IP rating (if outdoors).

- Package & Accessories: Include dust caps y shutters where contamination or laser safety is a concern.

Installation: Step-by-Step Best Practices

Tools & Materials: Fiber cleaning kit (lint-free wipes, 99% IPA or fiber cleaning solution, one-click cleaner), inspection microscope, power meter/LS or OTDR (optional), proper PPE for laser safety.

- Verify Part Numbers & Labels: Ensure you have Carolina del Sur/APC adapters and connectors (look for the green color code).

- Inspect & Clean: Use a scope to inspect connectors; clean until you achieve an “IEC pass.” Never insert a dirty connector.

- Mount the Adapter: For flanged types, secure to the bulkhead/panel using screws or snap-in clips.

- Insert First Connector: Carefully push the SC/APC connector straight into the adapter until it clicks/locks.

- Insert the Second Connector: Repeat from the opposite side. Avoid bending or twisting while inserting.

- Test the Link: Use a light source + power meter to verify IL, or an OTDR to characterize the event (optional but recommended for critical links).

- Cap Unused Ports: Keep dust caps on any unused side to protect the sleeve and prevent contamination.

Pro tip: Adopt the “Inspect–Clean–Inspect” routine every time you mate or re-mate connectors. Most fiber link issues stem from contamination.

Troubleshooting Common Problems

- High Insertion Loss: Likely due to contamination, damaged ferrule end-face, misalignment, or a worn sleeve. Clean, re-test, and replace if needed.

- Poor Return Loss / High Reflectance: Mismatched polish (APC mated to UPC), chipped ferrule, or worn alignment sleeve.

- Intermittent Performance: Mechanical wear after many mating cycles, temperature cycling, or poorly mounted bulkhead.

- Connector Won’t Latch: Check key orientation, latch damage, or deformed housing.

Maintenance & Handling Tips

- Always cap unused adapters and connectors.

- Store in sealed bags with desiccant for spares.

- Avoid over-tightening panel screws that can warp the adapter and misalign the sleeve.

- Track mating counts for mission-critical links; schedule preventive replacement.

- Keep cleaning tools (one-click cleaners, wipes) at every patch panel.

Glossary (Quick Reference)

- SC: Square/Subscriber Connector, 2.5 mm ferrule, push-pull latch.

- APC: Angled Physical Contact (8°) for ultra-low back reflection.

- UPC: Ultra Physical Contact (near-flat) polish, lower RL than APC.

- Pérdida de inserción (IL): Power lost when the signal passes through a component (dB).

- Pérdida de retorno (RL): Measure of reflected power; higher is better (dB).

- Zirconia Sleeve: High-precision ceramic alignment sleeve.

- PON: Passive Optical Network (e.g., GPON, XGS-PON).

- OTDR: Optical Time-Domain Reflectometer for link testing.

SC/APC Fiber Optic Adapter – FAQs

1. What does SC/APC mean?

CAROLINA DEL SUR is the connector type (Square/Subscriber Connector). APC refers to the 8° angled polish that yields ultra-low reflections.

2. Can I mate an SC/APC connector with an SC/UPC adapter?

No. You should never mix APC and UPC—you will get high loss, poor RL, and potential damage.

3. Why are SC/APC adapters green?

Green is the industry’s visual code for APC. It helps technicians avoid mismatches in the field.

4. What insertion loss should I expect?

For quality SC/APC adapters, ≤ 0.2 dB typical is common, though datasheets may specify up to 0.3–0.5 dB max.

5. What return loss should I expect?

≥ 60 dB is typical for APC connections, much better than UPC.

6. Are SC/APC adapters only for single-mode fiber?

Almost always yes. APC polishing is typically used in single-mode systems; multimode uses PC/UPC (not angled).

7. What’s the difference between simplex and duplex SC/APC adapters?

simplex handles one fiber. Dúplex houses two SC/APC channels side-by-side (often for Tx/Rx).

8. Do I need zirconia sleeves?

For high-performance, high-density, or carrier-grade networks, yes—zirconia ceramic sleeves provide better alignment and durability.

9. Can I reuse SC/APC adapters indefinitely?

They have a finite mating life (often 500–1,000 cycles). Replace if IL/RL degrades or if you see mechanical wear.

10. How do I test an SC/APC adapter’s quality?

Use a light source & power meter for IL, an OTDR for reflective events, and verify certified IL/RL test reports from your supplier.

Final Thoughts

A SC/APC fiber optic adapter may look like a simple plastic block, but it has outsized impact on your network’s optical budget, reliability, and reflection sensitivity. By understanding how APC works, paying attention to key specs like IL/RL, choosing zirconia sleeves for precision links, and following rigorous cleaning and testing practices, you’ll ensure your PON, CATV, or 5G network performs exactly as intended.

If you’re building or upgrading an FTTH or CATV plant and need help selecting the best SC/APC fiber optic adapter for your budget and performance targets, feel free to reach out—we can help you match the right grade, sleeve material, and environmental rating to your deployment.

Our Email: [email protected]