When it comes to installing fiber optic cables in underground environments, two main methods come into play: cable on cable and cable in fabric innerduct. We conducted a controlled experiment to see how each method fared under pressure, literally.

The Equipment:

- Cable: 13mm OD PE Fiber Optic Cable (standard size for fiber optic applications)

- Outer Duct: 50mm ID PE Pipe (common duct size for underground installations)

- Innerduct: FiberCheap 2″ 2-Cell Fabric Innerduct (a popular option of fabric innerduct)

- Test Parameters:

- Pulling Tension: 140 kg (represents a typical pulling force during cable installation)

- Pulling Speed: 25 meters / minute

- Pulling Duration: 10 minutes (equivalent to 250 meters), 20 minutes (500 meters), 30 minutes (750 meters)

The Test:

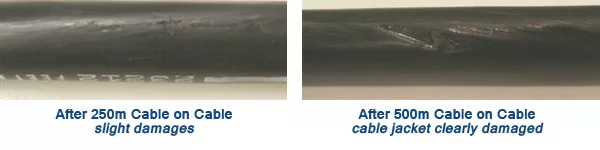

- Cable on Cable: We secured a cable within the outer duct. Another identical cable was rotated over the fixed cable at a set speed and tension, simulating a cable crossing scenario. This was repeated for durations representing 250m, 500m, and 750m cable pulls. We then inspected the cables for any sheath damage.

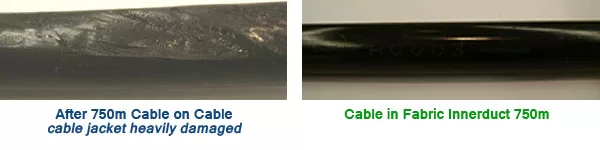

- Cable in Fabric Innerduct: The same test was conducted, but this time with the cable secured within the fabric innerduct, utilizing the second cell for cable rotation.

The Results:

Cable on Cable Passed at 250m, Failed at 500m and 750m:

The Cable on Cable method showed minor abrasions at 250 meters, but significant sheath damage at both 500 and 750 meters. We observed large amounts of plastic flaking from the outer duct, suggesting potential for signal failure at higher pulling tensions or longer distances.

Fabric Innerduct Passed at 750m:

The cable within the fabric innerduct exhibited only minor abrasions on the sheath. While the innerduct itself sustained a small tear (75mm) where the cables crossed, it did not expose the cable to any significant damage. Notably, the cable was in a continuous 10-meter loop, meaning the innerduct saw the cable pass over it at least 75 times during the test, demonstrating its resilience.

Conclusion:

This experiment clearly demonstrates the superior protection offered by fabric innerduct. While Cable on Cable might be suitable for low-risk, short-distance applications, fabric innerduct provides a significant advantage for critical infrastructure, longer cable runs, and situations with potential for damage. Its ability to withstand repeated cable passes and higher pulling tensions makes it a reliable choice for safeguarding your valuable fiber optic cables.