When it comes to installing fiber optic cables, electrical wiring, or utility lines through conduit, Polyester Pull Tape—also known as Mule Tape—is an essential tool. Its primary function is to assist in pulling cables through conduits with minimal friction and maximum strength. Choosing the right Polyester Pull Tape is critical for the safety, efficiency, and success of your cable-pulling operations. As a professional manufacturer of Polyester Pull Tape with various lengths and tensile strength options, we understand the key factors that make a difference in real-world applications.

This comprehensive guide will walk you through everything you need to consider when selecting the most suitable Cable Pull Tape for your project, from material properties to sizing, labeling, and environmental resistance.

What is Polyester Pull Tape?

Polyester Pull Tape is a high-strength, low-friction flat pulling tape made from woven polyester fibers. It is widely used in the telecom, electrical, and construction industries for pulling cables, wires, or fiber optic bundles through conduit systems. Its flat profile helps distribute pulling forces evenly, reducing damage to both the tape and the conduit interior. Unlike traditional ropes, Polyester Pull Tape is designed to resist elongation, abrasions, and weather exposure, making it a long-lasting and reliable solution.

Key Features of Polyester Pull Tape

Before diving into selection criteria, it’s essential to understand the built-in advantages:

- High Tensile Strength: Supports heavy cable loads with options ranging from 400 lbs to 6,000 lbs.

- Low Friction Coating: Minimizes pulling resistance and reduces the risk of cable damage.

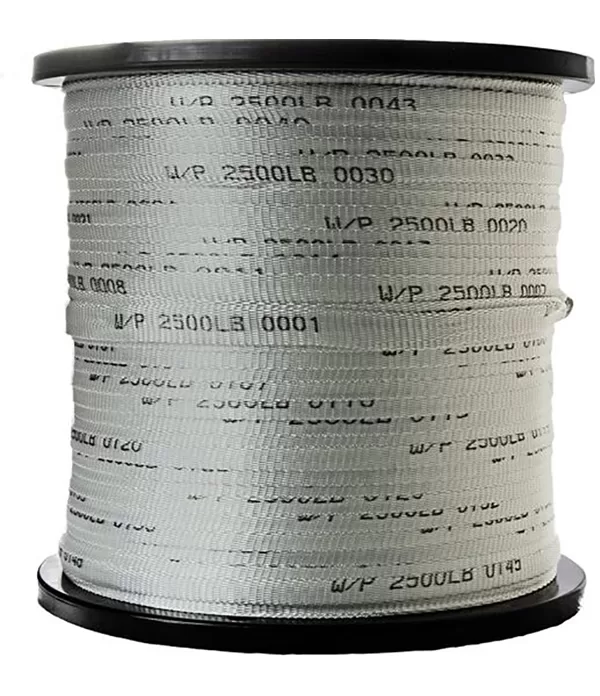

- Pre-Printed Footage Markings: Allows users to measure cable runs accurately and track installation progress.

- Abrasion and Chemical Resistance: Withstands rough conduit edges and exposure to lubricants or moisture.

- Compact and Lightweight: Easier to store and handle than traditional pulling ropes.

Factors to Consider When Choosing Polyester Pull Tape

1. Tensile Strength

One of the most critical specifications is the tape’s tensile strength, which refers to the maximum pulling force it can withstand before breaking. You must match the tape’s strength to the weight and type of cable being pulled.

Typical Strength Ranges:

- 400–1,250 lbs: Light-duty telecom or small conduit runs.

- 1,800–2,500 lbs: Standard fiber optic or coaxial cables.

- 3,000–6,000 lbs: Heavy-duty electrical, power cables, or multiple cable bundles.

Tip: Always choose a tape rated at least 25–30% higher than your estimated load to account for friction and potential snags.

2. Tape Width

The width of the tape impacts both its strength and compatibility with your conduit or duct system. Wider tape generally offers higher strength and better friction distribution but may not suit smaller conduits.

Common Sizes:

- 1/2 inch (light-duty)

- 5/8 inch (medium-duty)

- 3/4 inch and 1 inch (heavy-duty)

Always ensure the width matches both your conduit size and the strength requirements.

3. Tape Length

Polyester Pull Tape is available in various spool lengths, typically ranging from 500 feet to 6,000 feet. Choose a length that suits your installation path to avoid splicing multiple sections, which can reduce efficiency and strength.

Pro Tip: For long conduit runs, pre-lubricated or low-friction variants can make pulling easier and reduce cable damage risk.

4. Footage Marking and Traceability

Most professional-grade pull tapes feature sequential footage markings printed at regular intervals (usually every foot or meter). These markings allow:

- Accurate measurement of cable runs

- Easier inventory tracking

- Better project documentation

Some advanced tapes also feature QR codes or color-coding for easy identification of strength ratings and batch numbers.

5. Lubrication & Coatings

To enhance performance, some Polyester Pull Tapes are coated with a low-friction polymer or pre-lubricated to further reduce pulling resistance. These options are especially useful for long or complex conduit runs and help to minimize the risk of cable sheath damage.

Look for tapes with the following coatings:

- Silicone-based coatings (for very low friction)

- Water-resistant treatments (for outdoor and wet conditions)

6. Environmental Resistance

If your installation will expose the tape to moisture, UV rays, chemicals, or fluctuating temperatures, choose a Polyester Pull Tape specifically designed for durability under such conditions.

Key resistance features include:

- UV-stabilized fibers for outdoor use

- Mildew and mold resistance

- Hydrophobic coatings for wet or submerged conduits

- High heat resistance for installations in warm climates or near electrical loads

7. Aplikasi

Each project may demand a different type of Polyester Pull Tape depending on your application. Below are common use cases and corresponding tape recommendations:

| Permohonan | Recommended Tensile Strength | Suggested Width |

|---|---|---|

| Fiber optic cable pulling | 1,250–2,500 lbs | 5/8″ or 3/4″ |

| Electrical wiring | 1,800–3,000 lbs | 3/4″ |

| Heavy power cable | 3,000–6,000 lbs | 1″ |

| Directional drilling / OSP | 2,500–6,000 lbs | 3/4″ or 1″ |

| Subsurface duct installation | 1,250–2,500 lbs | 5/8″ |

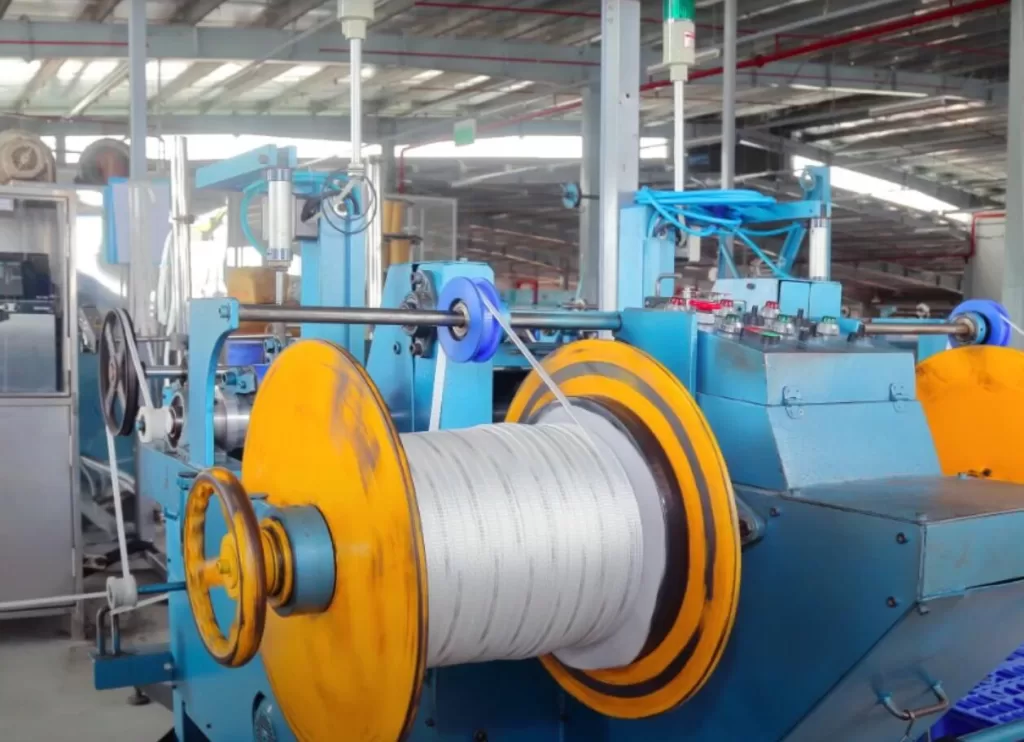

8. Packaging and Reel Options

Depending on the scale and nature of your work, you can order Polyester Pull Tape in different packaging options such as:

- Plastic reels for lightweight, portable use

- Wooden drums for long-length or heavy-duty projects

- Collapsible or refillable reels for field convenience

Make sure the packaging fits your jobsite logistics and equipment compatibility.

9. OEM Customization Options

As a trusted manufacturer, we also provide customized solutions to meet your branding or project-specific needs. OEM options may include:

- Custom tensile strength and width

- Branded packaging with logos

- Colored tapes for organizational purposes

- Special coatings for niche environments

- Low minimum order quantities (MOQs) for custom builds

Why Polyester Pull Tape Outperforms Traditional Rope

You might wonder why not just use a traditional rope. Here’s why Polyester Pull Tape is superior:

- Flatter profile reduces friction and prevents conduit abrasion

- Pre-labeled for measurement—no guesswork needed

- Greater tensile strength-to-weight ratio

- Lower elongation, preventing sudden snapbacks under tension

- Enhanced durability in outdoor and industrial environments

Summary: Choosing the Right Polyester Pull Tape

To sum it up, here’s what to consider when selecting the ideal Polyester Pull Tape:

- Tensile strength based on cable weight

- Width to match conduit and force distribution

- Length for uninterrupted pulls

- Environmental factors like moisture, UV, or chemical exposure

- Low-friction coating for easier installation

- Footage marking for accurate pulls and inventory

- OEM customization for specialized projects

With the right Polyester Pull Tape, you’ll reduce labor time, protect your cables, and ensure a smooth and safe installation.

Partner with Us for Your Polyester Pull Tape Needs

As a dedicated manufacturer of Polyester Pull Tape and Mule Tape, we offer:

- A wide range of strengths (400–6,000 lbs) and sizes

- Pre-lubricated, footage-marked, and UV-resistant variants

- Quick turnaround and global shipping

- Full OEM/ODM customization

- Competitive pricing and low MOQs

Whether you’re a telecom contractor, utility provider, or electrical installer, our factory-direct pull tape solutions are engineered for strength, reliability, and performance.

Contact us today to request a sample or get a custom quote for your next project.

Our Email: [email protected]