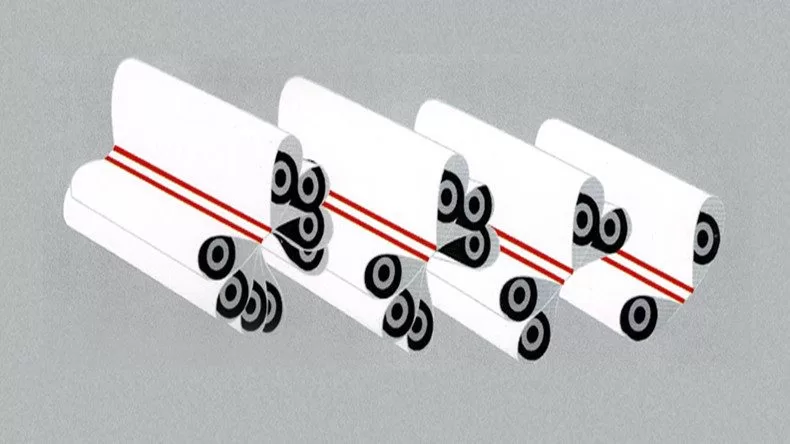

With the continuous popularization of emerging technologies such as 5G, Internet of Things, and cloud computing, people’s dependence on and demand for telecommunication networks are also growing. In order to meet this demand, telecommunication operators are constantly upgrading and expanding their network infrastructure. In this process, outdoor cabling systems play a vital role. The quality and reliability of outdoor cabling systems directly affect the performance and service quality of the entire telecommunication network. Therefore, choosing appropriate outside plant materials is crucial for communication operators. This article will introduce an excellent outdoor cabling material, the optical fiber inner conduit (ท่อชั้นในของผ้า) in the optical fiber cabling system, and discuss why it is suitable for the laying of outdoor optical cables.

There are several reasons why fabric innerduct is a good choice for outside plant (OSP) cabling:

- Flexibility: Fabric innerduct is very flexible, making it easy to install in tight spaces and around obstacles. This is especially important in OSP applications, where there may be limited access or where the cable needs to be routed around existing infrastructure.

- ความทนทาน: Fabric innerduct is made from durable materials that are resistant to crushing, impact, abrasion, corrosion, and chemicals. This makes it well-suited for the harsh environments that OSP cabling can be exposed to.

- Protection: Fabric innerduct provides a protective layer for the cables inside it. This helps to protect the cables from damage caused by moisture, dust, and other environmental factors.

- Ease of installation: Fabric innerduct is easy to install and can be done using a variety of methods. This makes it a cost-effective and efficient solution for OSP cabling projects.

In addition to these general benefits, fabric innerduct also offers a number of specific advantages for OSP cabling, including:

- Reduced risk of damage: Fabric innerduct helps to reduce the risk of damage to OSP cables during installation and maintenance. This is because fabric innerduct is less likely to kink or crush than other types of innerduct, such as PVC.

- Increased cable capacity: Fabric innerduct allows for more cables to be installed in a single conduit. This can help to reduce the cost and complexity of OSP cabling projects.

- Extended cable life: Fabric innerduct can help to extend the life of OSP cables by protecting them from the elements and other environmental factors.

Overall, fabric innerduct is a good choice for OSP cabling because it is flexible, durable, protective, and easy to install. It also offers a number of specific advantages for OSP cabling, such as reduced risk of damage, increased cable capacity, and extended cable life.

Here are some specific examples of OSP cabling applications where fabric innerduct is a good choice:

- Underground cabling: Fabric innerduct is ideal for underground cabling because it is resistant to crushing and corrosion.

- Aerial cabling: Fabric innerduct is also a good choice for aerial cabling because it is flexible and lightweight.

- Direct burial cabling: Fabric innerduct can also be used for direct burial cabling, but it is important to choose a fabric innerduct that is specifically designed for this application.

- FTTx cabling: Fabric innerduct is a good choice for FTTx cabling because it allows for more cables to be installed in a single conduit and it helps to protect the cables from damage.

If you are considering using fabric innerduct for your OSP cabling project, it is important to consult with a qualified professional to ensure that you choose the right type and size of innerduct for your specific needs.