Fabric innerduct and HDPE conduit are both commonly used to protect fiber optic cables. However, they have different advantages and disadvantages, making them more suitable for specific applications.

Fabric Innerduct

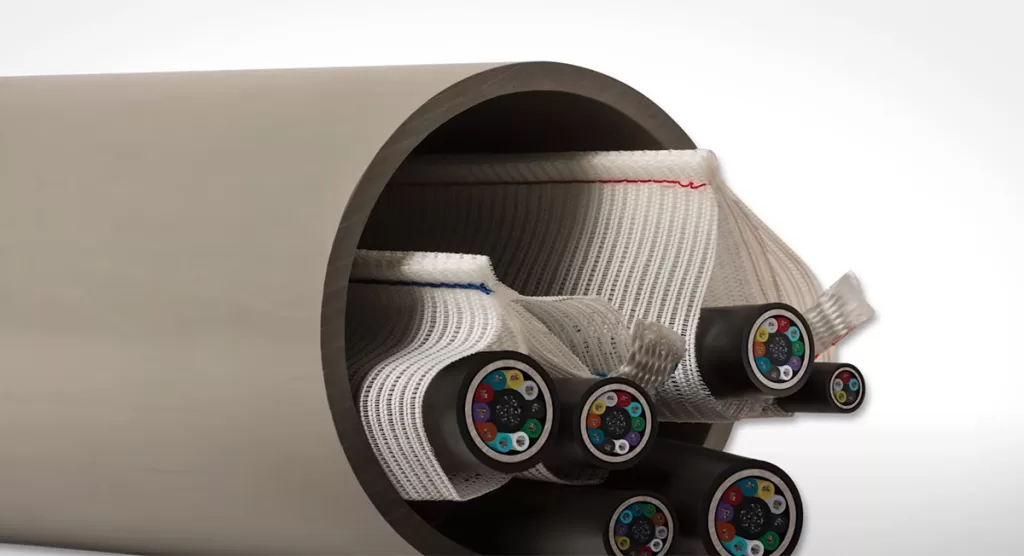

Fabric innerduct is a flexible, lightweight, and durable type of innerduct made from woven or braided synthetic fibers. It is resistant to abrasion, corrosion, and chemicals, making it ideal for use in a variety of environments, including underground installations, coastal areas, and industrial facilities.

HDPE Conduit

HDPE conduit is a rigid, strong, and durable type of innerduct made from high-density polyethylene. It is resistant to crushing, impact, and chemicals, making it a good choice for applications where the innerduct will be exposed to harsh conditions or heavy traffic.

Benefits of Fabric Innerduct over HDPE Conduit

Here are some of the key benefits of using fabric innerduct over HDPE conduit for fiber optic cable:

- Flexibility: Fabric innerduct is much more flexible than HDPE conduit, making it easier to install in tight spaces and around obstacles. This is especially important in complex installations, such as data centers and underground cable runs.

- Weight: Fabric innerduct is much lighter than HDPE conduit, which can reduce shipping and installation costs. This is especially critical for large-scale installations.

- Abrasion resistance: Fabric innerduct is more resistant to abrasion than HDPE conduit, which can help to protect the fiber optic cables from damage during installation and maintenance. This is especially important in applications where the cables may be exposed to friction or rubbing.

- Corrosion resistance: Fabric innerduct is resistant to corrosion, making it ideal for use in harsh environments such as coastal areas, industrial facilities, and underground installations. HDPE conduit is also resistant to corrosion, but fabric innerduct is generally considered to be more resistant.

- Multiple compartments: Some fabric innerducts have multiple compartments, which can be used to separate different types of cables or to organize cables by destination. This can help to improve cable management and reduce the risk of cable entanglement. HDPE conduit typically does not have multiple compartments.

Other Benefits of Fabric Innerduct

In addition to the key benefits listed above, fabric innerduct also offers a number of other advantages, including:

- Reduced installation time: Fabric innerduct is easier to install than HDPE conduit, especially in tight spaces and around obstacles. This can lead to significant time savings, especially on large-scale projects.

- Reduced maintenance costs: Fabric innerduct is less likely to be damaged during installation and maintenance than HDPE conduit. This is because fabric innerduct is more flexible and resistant to abrasion.

- Increased cable capacity: Fabric innerduct can accommodate more cables than HDPE conduit of the same diameter. This is because fabric innerduct is more flexible and can be packed more tightly.

- Improved environmental performance: Fabric innerduct is made from renewable resources and is recyclable, making it a more environmentally friendly option than HDPE conduit.

Applications for Fabric Innerduct

Fabric innerduct is a versatile solution that can be used in a variety of applications, including:

- Data centers: Fabric innerduct is ideal for use in data centers due to its flexibility, light weight, and ability to accommodate a large number of cables.

- Underground installations: Fabric innerduct is a good choice for underground installations due to its resistance to corrosion and abrasion.

- Coastal areas: Fabric innerduct is a good choice for coastal areas due to its resistance to corrosion.

- Industrial facilities: Fabric innerduct is a good choice for industrial facilities due to its resistance to chemicals and abrasion.

- Other applications: Fabric innerduct can also be used in a variety of other applications, such as telecommunications networks, broadband installations, and security systems.

Conclusion

Fabric innerduct offers a number of advantages over HDPE conduit for fiber optic cable applications, including flexibility, light weight, abrasion resistance, corrosion resistance, multiple compartments, reduced installation time, reduced maintenance costs, increased cable capacity, and improved environmental performance.

Fabric innerduct is a versatile solution that can be used in a variety of applications, including data centers, underground installations, coastal areas, industrial facilities, and telecommunications networks.

If you are considering using fabric innerduct for your fiber optic cable application, be sure to consult with a qualified professional to ensure that you choose the right type of innerduct for your specific needs.