Fiber optic drop cables are the critical link between the main fiber optic network and individual buildings or residences. They deliver the high bandwidth and low latency advantages of fiber optics directly to the end user. This comprehensive guide delves into fiber optic drop cables, exploring their types, applications, specifications, key considerations for deployment in 2024, and future trends shaping their design and functionality.

Types of Fiber Optic Drop Cables

Fiber optic drop cables come in various configurations to cater to diverse applications and environmental requirements. Here’s an overview of common types:

Aerial Drop Cables

- Designed for aerial deployments, suspended between poles or other overhead structures.

- Possess a strong outer jacket for weather resistance and protection against UV rays, high winds, and temperature fluctuations.

- May incorporate a metallic strength member for additional support.

Buried Drop Cables

- Built for underground installations, directly buried in trenches or conduits.

- Include a tough outer jacket with rodent-resistant properties to safeguard against animal bites.

- May have a water-blocking layer to prevent moisture ingress.

Direct Buried Drop Cables

- Specifically designed for direct burial without the need for conduits.

- Offer a cost-effective solution for underground deployments in areas with minimal risk of mechanical damage.

- Possess a robust outer jacket with superior crush resistance and moisture-blocking capabilities.

Indoor/Outdoor Drop Cables (Universal Drop Cables)

- Versatile cables suitable for both indoor and outdoor applications.

- Offer flexibility for routing within buildings and can withstand outdoor environments for short distances.

- May have a flame-retardant outer jacket for added safety indoors.

Fiber Optic Drop Cable Comparison

| Feature | Aerial Drop Cable | Buried Drop Cable | Direct Buried Drop Cable | Indoor/Outdoor Drop Cable |

|---|---|---|---|---|

| Typical Use Case | Aerial deployments | Underground installations (trenches, conduits) | Direct burial | Indoor and outdoor use |

| Key Characteristic | Weather resistance, UV protection, strength member | Rodent resistance, water blocking | Crush resistance, moisture blocking | Indoor/outdoor versatility, flame retardance (optional) |

Applications of Fiber Optic Drop Cables

Fiber optic drop cables play a vital role in delivering high-speed internet access and other bandwidth-intensive applications directly to users. Here are some key applications:

- FTTH (Fiber-to-the-Home): They are the final leg of the network, connecting the main fiber optic infrastructure to individual homes, enabling ultra-fast internet speeds and reliable connectivity.

- FTTB (Fiber-to-the-Building): These cables deliver fiber optic connectivity to multi-dwelling units (MDUs) like apartment buildings, dorms, or office complexes.

- Mobile Network Backhaul: Fiber optic drop cables are used to connect cell towers and other base stations to the core network, providing the high bandwidth required for mobile data traffic.

- Enterprise Fiber Optic Networks: They can be deployed within corporate campuses or industrial facilities to connect buildings and support data centers, security systems, and other bandwidth-demanding applications.

Specifications of Fiber Optic Drop Cables

Several key specifications define a fiber optic drop cable:

- Fiber Core Count: This refers to the number of individual glass fibers within the cable. Common options include single-mode (one core) for long-distance applications and multimode (two or more cores) for shorter distances.

- Fiber Type: The type of glass fiber used, such as standard G.652.D or bend-insensitive G.657.A, influences transmission characteristics and suitability for different deployment scenarios.

- Cable Diameter: The thickness of the cable, impacting ease of installation and bend radius limitations.

- Strength Member: The material used to provide tensile strength and support the cable, often metallic or aramid fibers.

- Outer Jacket Material: The material of the outer sheath, typically LSZH (low smoke, zero halogen) for fire safety or polyethylene (PE) for outdoor durability.

Typical Specifications of Fiber Optic Drop Cables

| Specification | Description | Example Values |

|---|---|---|

| Cable Diameter | Thickness of the cable | 2.0 mm, 3.0 mm, etc. |

| Strength Member | Material for tensile strength | Aramid fiber, Metallic wire |

| Outer Jacket Material | Material of the outer sheath | LSZH (fire safety), PE (outdoor durability) |

| Temperature Rating | Operational temperature range | -40°C to +85°C |

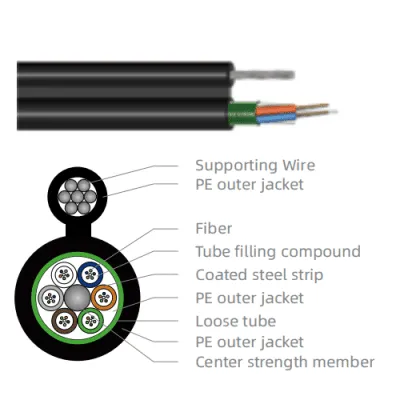

Understanding Cable Construction: Fiber optic drop cables typically consist of several layers:

- Central Buffer Tube(s): This protective tube houses the individual glass fibers.

- Strength Members: These elements provide structural support and prevent cable deformation.

- Filling Compound: This gel-like substance fills any gaps within the cable, protecting the fibers and improving cable integrity.

- Outer Jacket: The outermost layer safeguards the cable from environmental hazards and mechanical stress.

Configurations of Fiber Optic Drop Cables

Fiber optic drop cables can be pre-terminated with connectors on one or both ends for faster deployment. Here are common configurations:

- Non-terminated Cables: These cables require field termination with connectors at the deployment site. This offers flexibility for customization but requires additional installation expertise.

- Pre-terminated Cables with One Connector (Pigtail): One end of the cable has a pre-installed connector, simplifying connection to existing equipment. The other end is left unterminated for field installation.

- Pre-terminated Cables with Connectors on Both Ends (Patch Cables): Both ends of the cable come pre-equipped with connectors, allowing for quick and easy deployment between equipment.

The choice of configuration depends on factors like project scale, desired deployment speed, and in-house expertise for field termination.

Considerations for Deploying Fiber Optic Drop Cables in 2024

Here are some key factors to consider when deploying fiber optic drop cables in 2024:

- Application Requirements: Select the appropriate cable type (aerial, buried, etc.) based on the deployment environment. Consider factors like weather conditions, burial depth, and rodent risk.

- Fiber Core Count and Type: Choose the core count (single-mode or multimode) and fiber type (e.g., G.657.A for bends) that align with your network’s transmission distance and bandwidth requirements.

- Cable Specifications: Ensure the cable diameter, strength member type, and outer jacket material are suitable for the installation method and environmental conditions.

- Deployment Expertise: Evaluate your in-house expertise for field termination or consider pre-terminated options for faster deployment.

- Future Scalability: Opt for cables with sufficient fiber core count to accommodate potential future bandwidth needs.

Future Trends in Fiber Optic Drop Cable Design

The future of fiber optic drop cables is likely to be shaped by the following trends:

- Microsized Cables: Advancements in fiber optic technology may lead to even thinner and more flexible drop cables, facilitating easier installation in tight spaces.

- Bend-Insensitive Fibers: The continued development of bend-insensitive fibers will offer greater installation flexibility and reduce signal attenuation caused by bending.

- Integrated Intelligence: Smart drop cables with embedded sensors could offer real-time monitoring capabilities for proactive maintenance and improved network management.

- Focus on Sustainability: The use of environmentally friendly materials and recyclable components in drop cable construction is expected to gain traction.

By understanding the types, applications, specifications, and deployment considerations of fiber optic drop cables, you can make informed decisions when selecting and implementing these crucial components for your high-speed fiber optic network. With continuous advancements in technology, fiber optic drop cables are poised to play an even more significant role in delivering reliable and high-bandwidth connectivity directly to users.

FiberCheap is a professional Fiber Optic Drop Cable Manufacturer with 14 years of experience, if you’re looking for a FTTH Fiber Drop Cable solution that offers superior quality, durability and cost-effectiveness, please feel free to contact us.