Fiber optic splicing is the process of joining two fiber optic cables together to create a continuous path for data transmission. It is a critical process in the installation and maintenance of fiber optic networks.

Types of Fiber Optic Splicing

Mechanical splicing

Mechanical splicing is a relatively simple process that involves using a special tool to align and hold the two fiber optic cables together. It is a good option for quick and easy repairs, but it does not result in as strong of a connection as fusion splicing.

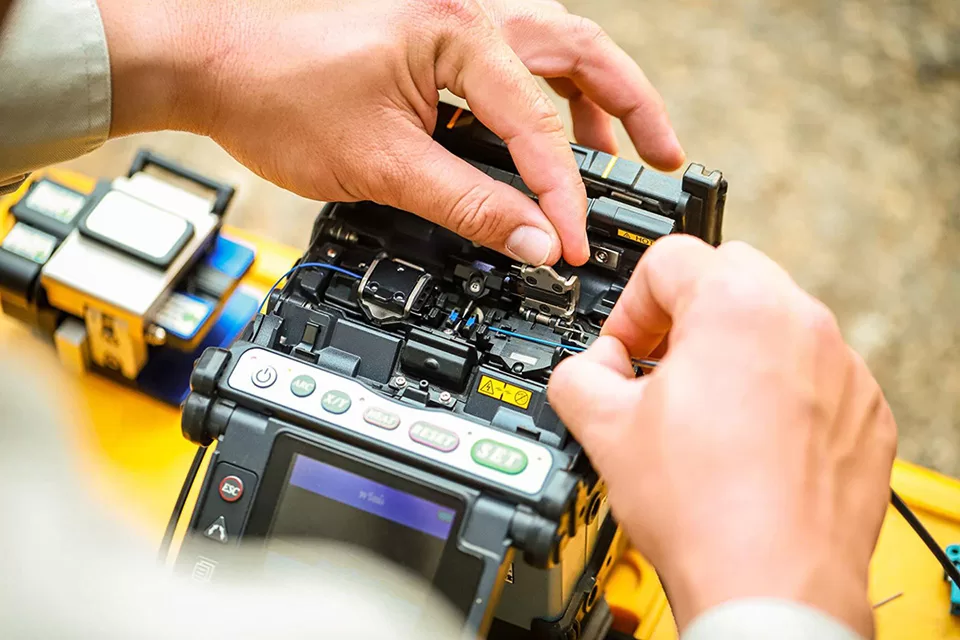

Fusion splicing

Fusion splicing is a more complex process that involves using an electric arc to melt the two fiber optic cables together. This results in a very strong and permanent connection. Fusion splicing is the preferred method for joining fiber optic cables in high-performance networks.

Benefits of Fiber Optic Splicing

- It allows for the creation of longer fiber optic cable runs.

- It allows for the connection of different types of fiber optic cables, such as single-mode and multimode cables.

- It allows for the repair of damaged fiber optic cables.

- It can be used to create custom fiber optic cable assemblies.

Fiber Optic Splicing Applications

- Telecommunications networks

- Data center networks

- Local area networks (LANs)

- Wide area networks (WANs)

- Industrial control systems

- Military and aerospace applications

Splicing Process

The splicing process can be broken down into the following steps:

- Preparation: The fiber optic cables are prepared by stripping the outer jacket and buffer coating from the ends of the cables. The fiber optic cores are then cleaned to remove any dust or debris.

- Alignment: The fiber optic cores are aligned using a special tool called a cleaver. The cleaver creates a precise and perpendicular cut on the end of each fiber optic core.

- Splicing: The fiber optic cores are spliced together using either mechanical splicing or fusion splicing.

- Testing: The splice is tested to ensure that it is strong and that the light transmission is good.

Splicing Equipment

The following equipment is typically used for splicing:

- Fiber optic cleaver

- Fiber optic stripper

- Fiber optic buffer stripper

- Fiber optic core cleaner

- Fiber optic splicer

- Optical time-domain reflectometer (OTDR)

Best Practices

When splicing fiber optic cables, it is important to follow the following best practices:

- Use clean and calibrated tools.

- Make sure that the fiber optic cores are properly aligned before splicing.

- Use the appropriate splicing method for the application.

- Test the splice to ensure that it is strong and that the light transmission is good.

Additional Information

Fiber optic splice closure is a type of fiber optic equipment used to provide storage space and protection for optical cables that are spliced together. FiberCheap is a leading supplier of fiber optic splice closures in China, ask for free quote now.