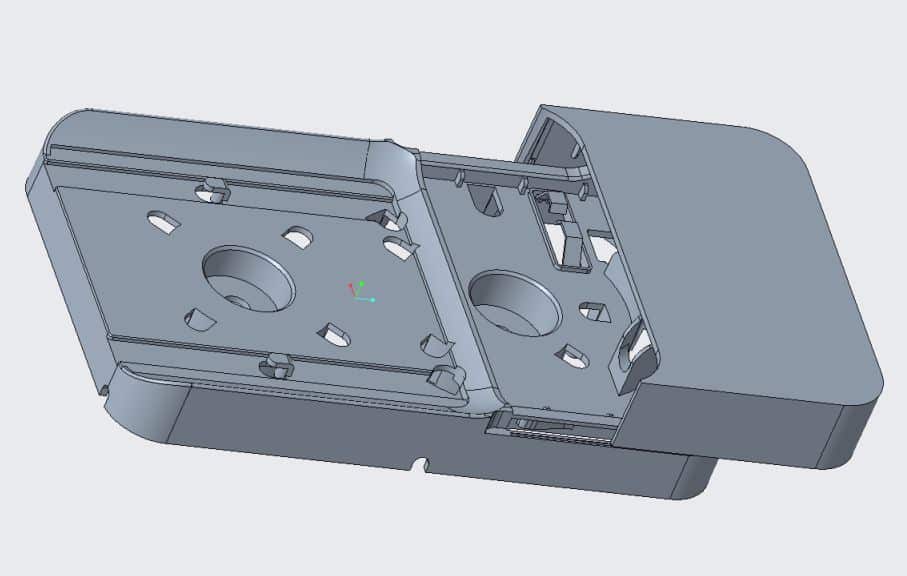

OEM/ODM fiber distribution box production refers to the process where manufacturers create and/or modify fiber distribution boxes according to the specific requirements of a customer. These boxes, also known as fiber optic distribution frames, are essential components in fiber optic networks as they manage, protect, and connect optical fibers, ensuring smooth transmission of optical signals.

Pros of OEM/ODM Fiber Distribution Box Production

Custom Solutions

OEM/ODM production allows customers to create custom solutions that fit their specific needs. By working with manufacturers, customers can customize the design, features, and functionality of fiber distribution boxes to meet their unique requirements. This can help customers optimize their fiber optic network for their specific applications and improve performance and efficiency.

Cost-Effectiveness

OEM/ODM production often results in cost-effective solutions because manufacturers can produce boxes in bulk quantities and enjoy economies of scale. Customers can purchase the boxes at a lower cost, which can help them save money and offer competitive prices in the market.

Time-to-Market

OEM/ODM production can help customers accelerate their time-to-market for new products or services. By working with manufacturers, customers can focus on their core business and worry less about the design and production of fiber distribution boxes. This can help them bring their products or services to market faster and capture market share.

Branding Opportunities

Customers can brand OEM/ODM fiber distribution boxes as their own, integrate them into their existing fiber optic network infrastructure, and offer them as a value-added service to their customers. This can help them differentiate themselves from competitors, strengthen their brand image, and win new business opportunities.

Flexibility

OEM/ODM production allows customers to have flexibility in production, quantity, and order size. They can adjust orders based on demand, seasonal changes, or special requests, allowing them to better manage their inventory and respond to market changes.

Cons of OEM/ODM Fiber Distribution Box Production

Risk of Loss of Control

When using OEM/ODM production, customers may risk losing control over certain aspects of the production process. Although manufacturers may adhere to quality standards, customers may lack the knowledge and experience to effectively monitor and ensure quality control over the entire production process.

Dependency on Manufacturer

Customers who use OEM/ODM production become dependent on the manufacturer for the supply of critical components. If the manufacturer experiences any issues or faces supply chain disruptions, it could have negative impacts on the customer’s operations.

Potential for Intellectual Property Issues

When using OEM/ODM production, there is a risk that customers may inadvertently infringe on someone else’s intellectual property rights. It is important for customers to carefully review all designs, patents, and trademarks to ensure that they do not violate any intellectual property laws or regulations.

Lack of Innovation

By outsourcing production to OEM/ODM manufacturers, customers may lose the opportunity to innovate and develop their own unique products or services. Instead, they are reliant on the manufacturer’s design and technology, which may limit their ability to stay competitive in the market.

Conclusion

It is very important to choose an excellent and reliable fiber distribution box manufacturer, which will provide quality assurance for your OEM/ODM products. A good manufacturer should have a professional technical team and advanced production equipment to provide you with high-quality design, manufacturing, and testing services to ensure that your OEM/ODM products meet the expected quality standards. In addition, manufacturers should provide reliable after-sales service, including technical support, maintenance and warranty, to ensure that your product operates reliably throughout its life cycle.